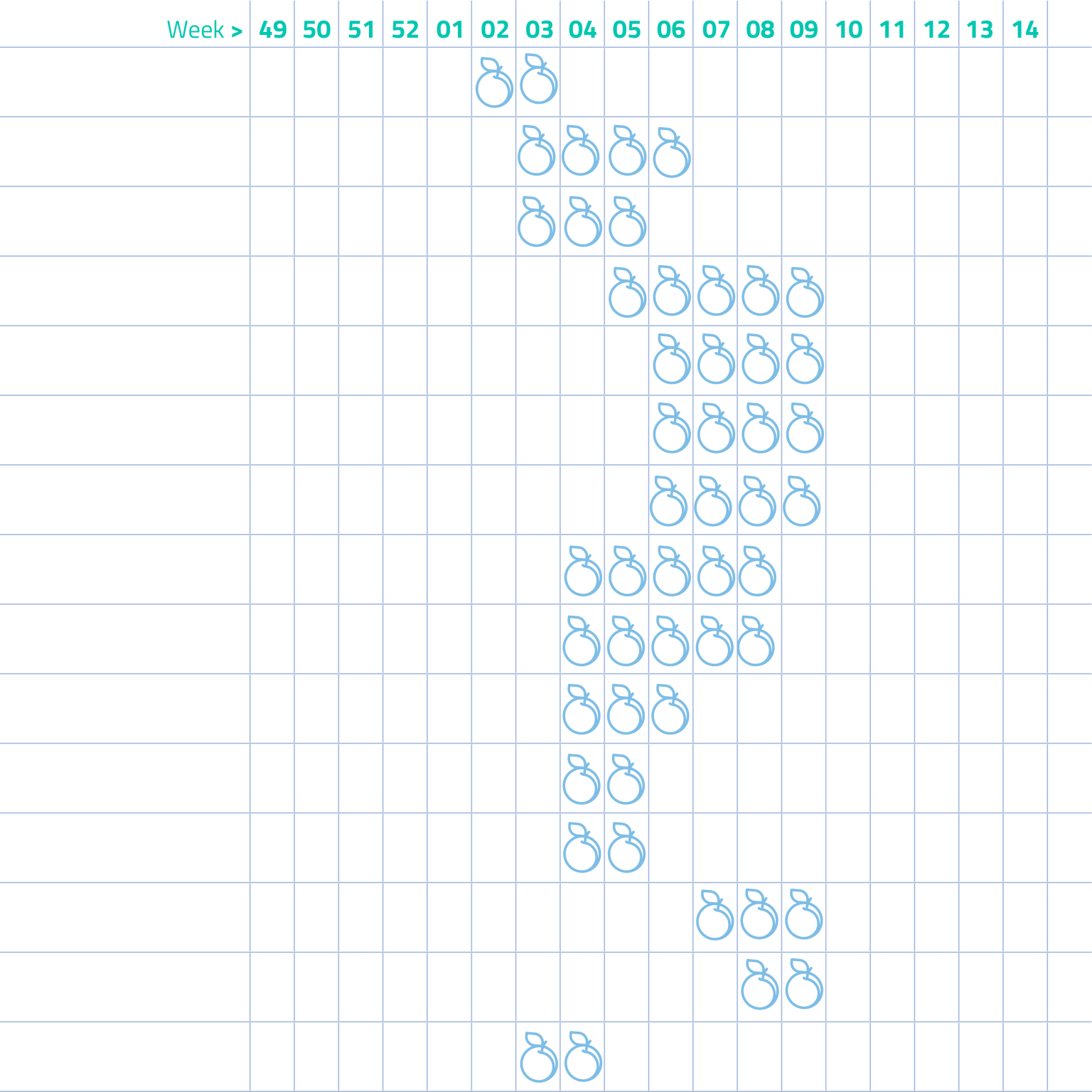

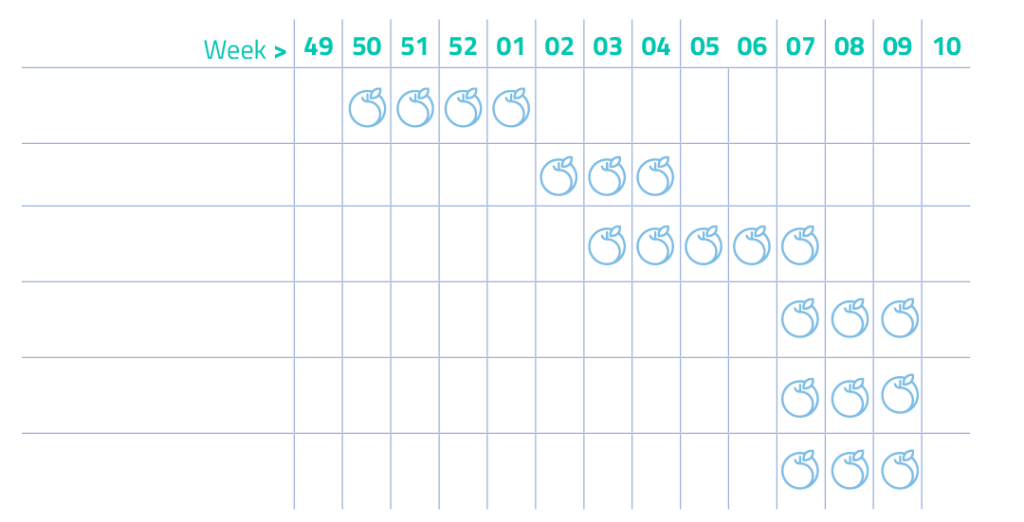

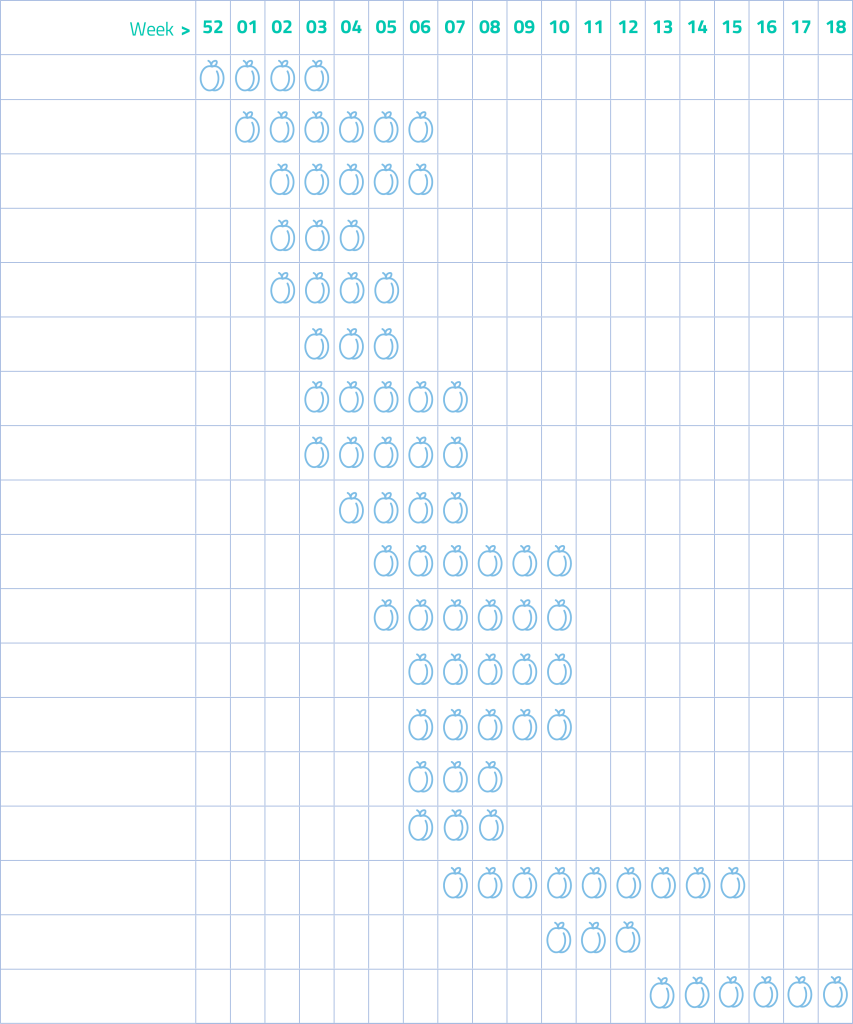

This season, the industry is facing a significant new challenge with the fruit fly, an issue that demands close collaboration with our growers. As we navigate this complex situation, our approach involves adapting both as a company and as an industry to meet the stringent requirements of major markets, particularly China.

How We Are Adapting

Company Adaptation: We are enhancing our protocols and investing in advanced technologies to manage fruit fly risks effectively. At our DDC Romeral packinghouse, located within a regulated area, we will have a dedicated team of internal refrigeration experts who will oversee the operation of thermographs installed in containers. These devices are crucial for monitoring and maintaining optimal temperatures to ensure fruit fly extermination, in strict compliance with international phytosanitary standards.

Industry Adaptation: We are working closely with industry stakeholders to coordinate efforts and streamline processes. This involves collaboration with growers, the Agricultural and Livestock Service (SAG), logistics & cargo shipping companies, and all other key actors in the supply chain. By aligning our strategies and sharing knowledge, we aim to address this challenge collectively and maintain high-quality standards for our exports.

Alternative Plans and Coordination

In addition to our primary protocols, we are developing alternative plans to further safeguard against the fruit fly. These include exploring new treatment technologies and methods to enhance our current systems. Coordination with our growers is essential, ensuring they are well-informed and equipped to manage fruit fly risks at the source.

We also maintain open lines of communication with SAG and logistics partners to address any potential issues promptly and effectively. This collaborative approach helps us stay ahead of challenges and adapt swiftly to evolving requirements.

For more detailed information on how to manage fruit fly risks, we have prepared a practical brochure for our growers. This resource provides valuable insights and guidance on best practices and protocols to follow. You can find the brochure attached below.

Together, we are committed to overcoming this challenge and ensuring that our fruit continues to meet the highest quality standards in global markets.